Pipe Nipples in HVAC Systems: Best Practices for Installation

- pcfspn1

- Dec 8

- 2 min read

When you work on heating, ventilation, and air conditioning (HVAC) systems, small parts can make a big difference. One of those small but very important parts is the pipe nipple. A pipe nipple is a short piece of pipe with threads on both ends. It helps connect fittings, valves, and equipment in HVAC piping.

Even though pipe nipples look simple, using the wrong type or installing them badly can cause leaks, noise, and expensive repairs. In this guide, we share easy best practices so your HVAC system stays strong and leak-free.

1. Choose the Right Material

Black steel pipe nipples – Most common and cheapest for gas lines and hot water heating.

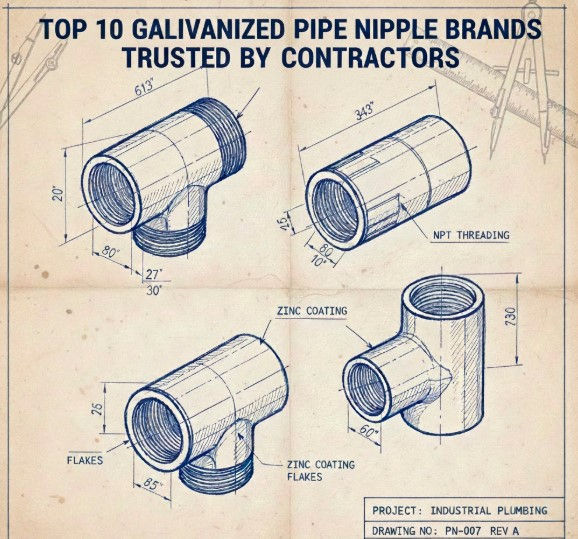

Galvanized pipe nipples – Good when you need protection from rust in air lines or outdoor units.

Stainless steel pipe nipples – Best for chilled water and places with high moisture.

Brass pipe nipples – Often used on refrigerant lines and condensate drains.

Tip: Never mix galvanized and black steel in the same system. They can rust fast when joined.

2. Pick the Correct Size and Schedule

Most HVAC work uses Schedule 40 pipe nipples. For high-pressure boiler rooms, use Schedule 80 or extra-strong (XS) nipples. Common sizes are ½", ¾", and 1" with NPT threads.

Always use “close nipples” only when space is very tight. A little longer nipple (2"–6") is easier to install and gives better thread engagement.

3. Use the Right Thread Sealant

For water and air lines → Yellow PTFE tape (2–3 wraps) or good quality pipe dope.

For natural gas or propane lines → Use yellow PTFE tape made for gas or gas-rated pipe dope only.

Never use white PTFE tape on gas lines – it is not safe.

4. Install Step by Step

Clean the threads on both the nipple and the fitting.

Apply sealant correctly.

Hand-tighten first, then use two wrenches (one holds, one turns) – never spin the valve or gauge.

Tighten only 1 to 1½ turns past hand-tight. Too much force cracks fittings.

Check for leaks with soapy water after you turn the system on.

5. Common Mistakes to Avoid

Using a close nipple when you have space for a longer one → less thread engagement = leaks.

Over-tightening → cracks fittings.

Forgetting dielectric unions when connecting copper to steel → fast corrosion.

Buying cheap imported nipples with bad threads → hard to install and quick to leak.

Trust a Reliable Pipe Nipple Manufacturer

When you need pipe nipples that fit perfectly and last long, choose Pcfspn. Pcfspn is a trusted pipe nipple manufacturer that makes black steel, galvanized, stainless steel, and brass nipples in all sizes. They check every piece for quality and ship fast so your job stays on schedule.

Contractors across the country use Pcfspn nipples because they install easily and never leak. Next time you work on an HVAC system, save time and money – get your pipe nipples from Pcfspn.

Comments